Navigating Copper Price Headwinds and Enabling Quantum Leap in Mass Production of Composite Current Collector—NAURA Achieves a Critical Breakthrough in Composite Current Collector Production Equipment

In the critical materials market for new energy, following successive price surges in cobalt, nickel, and lithium carbonate, copper and aluminum prices have also entered a sharp upward trend this year.

According to market data, Shanghai copper futures rose from RMB68,000 per ton in January to nearly RMB90,000 per ton, while copper material prices climbed from RMB30,000 per ton in 2020 to over RMB70,000 per ton today.Despite short-term volatility, the long-term bullish outlook for copper remains unchanged. The limited supply expansion, coupled with reduced long-term processing fees between copper miners and domestic smelters, is exerting profit pressures on smelting companies. Meanwhile, copper demand driven by new energy vehicles and charging infrastructure remains a major growth highlight.

Regarding aluminum prices, electrolytic aluminum reached its lowest point in February 2024, but from March onward, it surged strongly and hit a new peak in May, marking the highest level since April 2022. Looking ahead to the second half of the year, influenced by seasonal price patterns and supply-demand dynamics, aluminum prices are expected to maintain a strong upward trend.

As key raw materials for lithium battery industries, copper and aluminum primarily serve as current collector foils. Their price increases have directly pushed up the cost structure of battery cells. For example, with copper prices rising, copper foil now accounts for about 20% of battery cell material costs, becoming the second-largest cost component after cathode materials, according to data from GGII.

Historically, price volatility in upstream raw materials has caused significant shocks to the lithium battery industry, slowing its adoption.

To break free from dependence on single raw materials, the industry has pursued alternatives: cobalt-free cathodes to combat cobalt price hikes, rapid growth of lithium iron phosphate batteries in response to nickel surges, and active exploration of sodium-ion batteries amid rising lithium carbonate costs.

Now, the rising prices of copper and aluminum are driving a new wave of material substitution.

Among alternatives, composite current collectors have attracted wide attention due to their significant demetallization characteristics, and their industrialization is highly anticipated.

Gaogong Lithium Battery highlights that NAURA Vacuum has achieved a critical breakthrough in production equipment for composite current collectors, marking a pivotal moment for the industrialization of this material.

Beijing NAURA Vacuum Technology Co., Ltd., a wholly-owned subsidiary of NAURA, boasts nearly six decades of experience in vacuum heat treatment and surface treatment equipment R&D and manufacturing. As a leading force in China's high-end equipment manufacturing sector, it has a broad portfolio covering PVD and CVD coating equipment.

Leveraging years of market insight and technological accumulation, NAURA Vacuum ensures exceptional coating quality under high-efficiency operations, empowering innovation in the composite current collector industry and addressing the challenge of new material substitution amid rising copper prices in battery cells.

[Composite Current Collector Manufacturing Solutions Empower Cost Reduction and Efficiency]

Compared to traditional copper and aluminum foil solutions, composite current collectors stand out as next-generation polymer materials due to their superior safety, high performance, and cost efficiency.

For example, composite current collectors reduce material costs by nearly 40% and cut weight by approximately 60% compared to conventional copper foil. This material not only lowers battery manufacturing expenses but also significantly boosts energy density and safety. Concurrently, the composite current collector market is experiencing rapid growth. According to data from the GGII, the demand for 6-micron composite copper foil could reach 3.876 billion square meters by 2025 under optimistic forecasts, corresponding to a market value of RMB20.16 billion. By 2030, the penetration rate of composite copper foil is projected to rise to 22%.

Aligned with the trend toward quality and efficiency enhancement in composite current collectors, NAURA Vacuum has introduced a comprehensive product equipment matrix in recent years, based on its extensive technological foundation in vacuum coating. This includes the eMeridian RR-M/RR-R/RR-E series vacuum roll-to-roll coating systems, eHorizon HL series horizontal magnetron sputtering continuous coating equipment, eVorizon VL series vertical magnetron sputtering continuous coating equipment, and the eArctic series of standalone units, including AS500, AS600, AS700, AS14G, AS1100, EP1350 models, among others.

These offerings have enabled NAURA Vacuum to successfully enter the new energy sectors such as composite copper and aluminum foils, cathode and anode materials, solid-state batteries, and distributed energy storage, thereby driving technological innovation and enhancing cost-efficiency for lithium battery manufacturers.

Particularly in composite current collector manufacturing, where vacuum coating equipment demands are stringent, NAURA Vacuum's extensive coating equipment matrix realizes comprehensive industrial chain coverage in high-end manufacturing, laying a solid foundation for large-scale composite current collector production.

GGII reports that NAURA Vacuum's composite current collector equipment has secured orders from multiple leading customers and earned high recognition for its performance.

["Technology + Products" Forge Core Competitiveness]

Currently, composite current collectors are produced using dry methods in one-step, two-step, or three-step processes, with magnetron sputtering as the core technology. Magnetron sputtering forms thin films by bombarding target materials with inert gas ions in a vacuum environment, causing surface atoms to be ejected and deposited onto substrates.

However, without effective surface activation of the polymer film, the adhesion between the copper layer and the polymer substrate weakens. Furthermore, heat accumulation on the substrate surface during sputtering can damage the substrate itself, leading to uneven stress during winding and ultimately causing breaks or defects.

These intertwined issues collectively constrain yield improvements, increase production costs, and slow industrialization progress.

To overcome these technical challenges, NAURA Vacuum, a leader in the domestic PVD equipment field, has leveraged its profound vacuum technology expertise and continuous innovation to successfully expand from high-end semiconductor applications to industrial production—achieving a major breakthrough in composite current collector manufacturing.

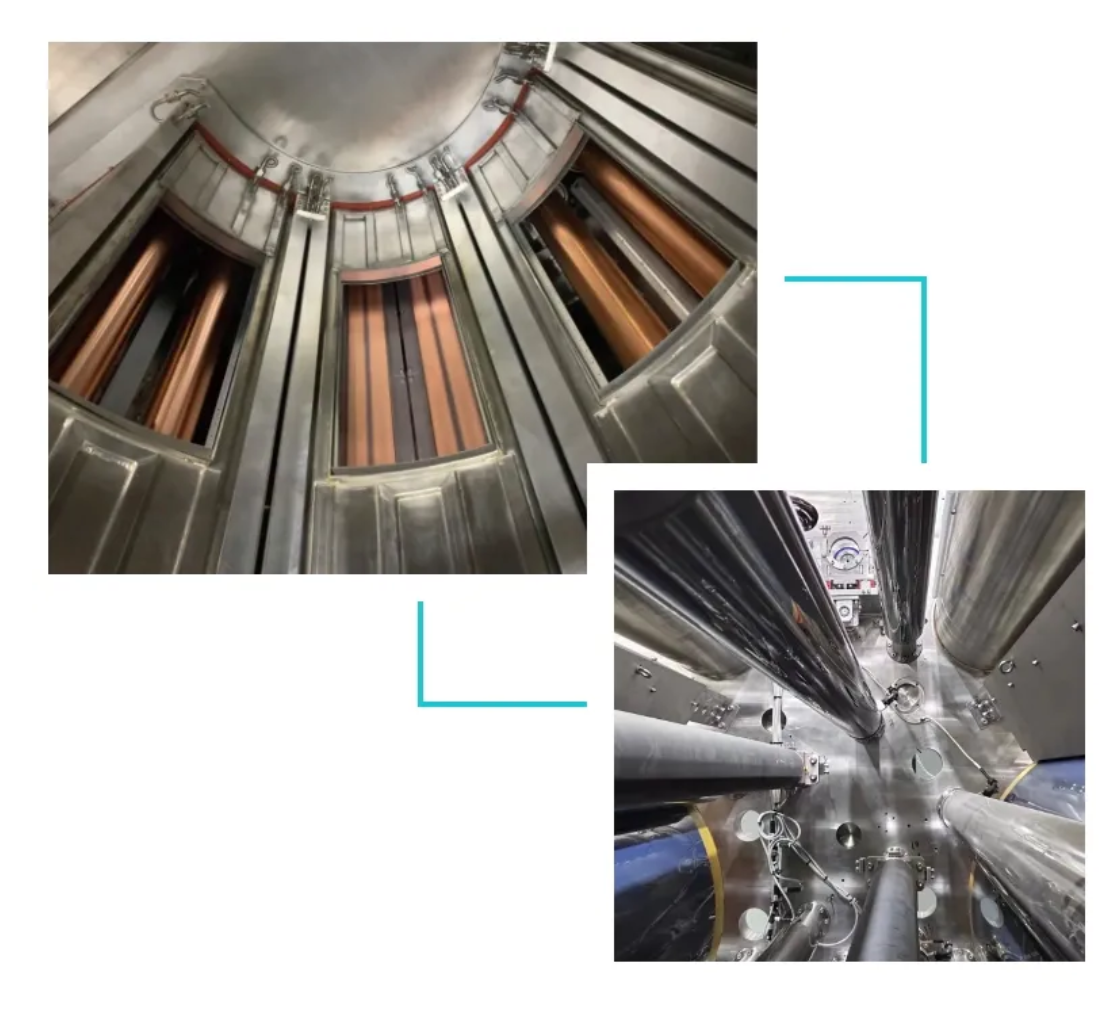

Its meticulously developed eMeridian RR-M magnetron sputtering roll-to-roll coating system and eMeridian RR-R wire-evaporation roll-to-roll coating system feature advanced roller designs, proprietary "Black Gold Drum" technology, refined thermal management, and specialized substrate surface treatment, effectively resolving the above issues.

These systems substantially boost production yield, reduce costs, and pave the way for large-scale industrialization.

① eMeridian RR-M Magnetron Sputtering Roll-to-Roll Coating System

Supports substrates such as PET, BOPP, PI, and SUS, with widths of 600–2,000 mm and thicknesses of 3–50 μm. Winding speeds range from 0.1 to 30 m/min, with tension control from 10 to 250 N. Production line speeds exceed 20 m/min, achieving 15,000 m of defect-free PET composite copper foil and enhanced adhesion for PP composite copper foil meeting shipment standards.

② eMeridian RR-R Wire-Evaporation Roll-to-Roll Coating System

Supports substrates 600–2,000 mm wide, 4.5–50 μm thick, winding speeds 0.1–100 m/min, and tension 10–250 N.

In addition, NAURA Vacuum integrates multiple innovative technologies into composite current collector production, elevating manufacturing efficiency and product quality through lean production methods.

① Roller System Design and Control Technology:

The proprietary intelligent winding control system (e-Web) ensures exceptional web stability during high-speed operation. By establishing mechanical models of the winding system and optimizing roller design, coupled with multi-stage tension control, the system enhances compatibility with various flexible substrates and broadens process adjustment windows, achieving stable winding and superior coating quality. Real-time monitoring of winding speed and tension data supports informed production decisions.

② Black Gold Drum Technology:

NAURA Vacuum's proprietary Black Gold Drum technology is integrated into both the eMeridian RR-M magnetron sputtering roll-to-roll coating system and the eMeridian RR-R wire evaporation roll-to-roll coating system. This technology employs specialized materials to treat the coating drum's surface, enhancing adhesion between the substrate and the drum, improving thermal management throughout the system, and ensuring consistent film quality.

③ Low-Temperature Magnetron Sputtering Technology:

To address thermal deformation issues in flexible polymer films, NAURA Vacuum independently developed cathode systems with innovative auxiliary anode designs and optimized magnetic field distribution, achieving highly uniform plasma distribution that substantially lowers substrate surface temperature during sputtering and boosts yield.

④ Wire Evaporation Technology:

An evaporation simulation model was developed to refine the design of the evaporation system, significantly enhancing coating uniformity. A closed-loop wire feeding control module was also engineered to maintain stable wire feeding, with real-time adjustments to wire landing position and angle on the evaporation boat, ensuring consistent material evaporation and greatly improving film uniformity.

⑤ Gas Ion Etching and Assisted Deposition Technology:

This technology enables effective surface cleaning and etching of the substrate, strengthening film adhesion and improving film quality. NAURA Vacuum has independently developed a linear ion source free of filaments and grids, offering a streamlined structure and extended lifespan. The source accommodates inert and reactive gas mixtures such as Ar, H₂, O₂, and C₂H₂, allowing it to function both as a reactive deposition source and as an auxiliary deposition enhancer, further elevating film quality.

As the lithium battery industry enters a period of structural transition, soaring raw material costs are intensifying pressure on manufacturers. The urgent need for cost reduction and efficiency gains is driving the search for next-generation solutions. Looking ahead, with its unique advantages, composite current collectors are expected to become standard in lithium battery applications.

Positioned at the forefront of this field, NAURA Vacuum is fully prepared to lead. With deep technical expertise and relentless process innovation, its advanced equipment will empower battery manufacturers to lower costs and boost efficiency—accelerating the industry's transformation toward a more efficient, greener, and sustainable future.